Any panel, any sheet, any size, any number of pieces or combination thereof, we can cut it for you.

Having your panels cut to size at Harbor saves you time and money, we’re at your service.

Use your portal or call your Harbor CSR, either way you’ll enjoy the most economical yield and the most accurate cut.

Optimize for lowest cost -

All you need to know is what sizes and how many pieces of each size your job requires. Once you have entered all of the sizes and number of pieces into your optimizer, your portal will automatically calculate the least expensive way to produce the parts you need.

How does it work?

Once it knows the sizes and number of cut to size pieces you require, your portal will look at all of the available full sheet materials. Next, the system will calculate the best way to cut the full panels to produce the best yield and least waste.

Entering your cut to size order

1. Select and order the panel you want to have cut

2. Go to your order worksheet

3. Select "cut it" from the Yes You Can column next to the panel you want to cut

4. The optimizer page will automatically open

5. Enter the width and length for your first cut piece (in decimal inches)

6. Enter the number of pieces that you need

7. Click the "save" icon

8. Continue to enter sizes and quantities until all of the pieces that you will need have been entered

9. Click on the "optimize" icon (upper right corner)

10.The portal will calculate the best way to produce the pieces that you require and show you a diagram of exactly how the panels will be cut

11.Check your sizes, and then click on UPDATE ORDER.

12.The portal will calculate any cutting charges, and add your requirements to your order.

13.You can additional items to your worksheet, and when you have completed your order, simply submit your order and we’ll take care of the rest. Dimensions- Decimal Inch

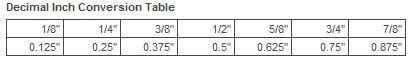

The portal will accept dimensions in full inch or decimal inch. There is a decimal inch conversion chart below for your convenience.

Nominal sizing

In some applications you may want to have your pieces cut slightly smaller sizes to reduce your costs. For example, if you need 10 pieces of 18” x 24” and you require full exact dimensions, it would require 2 sheets of 4’ x 8 ‘ material. If you select nominal sizing your optimizer will automatically adjust for the width of the saw blade, and your pieces will be cut approximately 3/16” smaller than the requested size. In the case of this example, you would then be able to cut all 10 pieces of 18 (nominal) x 24 (nominal) from one 4’ x 8’ sheet and enjoy a major reduction in your net cost.

Corner Rounding

Harbor will be happy to round the corners on any of your cut to size sheet metal orders. When you select your cut sizes, simply pull down the corner rounding tab, and select the radius you want us to use. Once selected, we will automatically round all four corners on each sheet

Remaining material

If your cut order will result in left over material, we will deliver all of the material with your order. Your optimizer will let you know what size your remaining material will be and your diagram will show you the configuration. Harbor always ships all of the material that you purchase.

Any questions, comments, recommendations or concerns, please feel free to give Harbor a call 800-345-1712